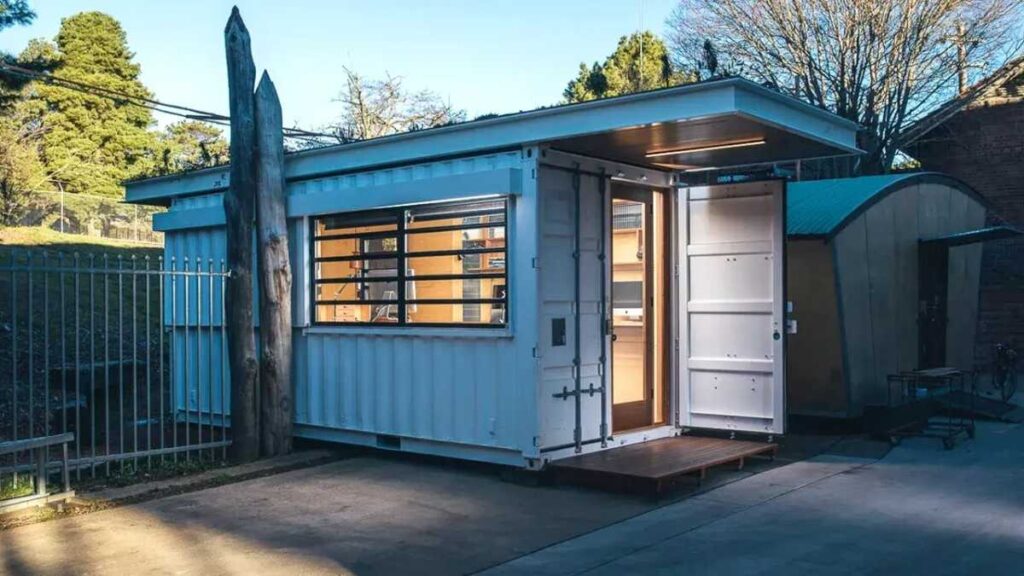

In recent times, shipping containers have emerged as a popular choice for creating unique and functional spaces. Their uses ranging from backyard studios to off-grid retreats. However, the standard shipping container roof ideas need significant modifications to transform these metal boxes into comfortable living spaces. In fact, the right roof can enhance insulation while adding modern style to these versatile structures.

The challenge lies in the container’s original flat roof design, which can sag over time and lead to drainage issues if not properly maintained. Additionally, factors like load-bearing capacity, dead load, and live load must be carefully considered when implementing shipping container roof modifications. Local environmental conditions, such as high winds or heavy rainfall, also play a crucial role in determining the most suitable roofing solution.

Let’s explore various shipping container roof designs, from practical shed roofs to innovative green roofs that improve insulation and reduce energy costs. Readers will discover how different roofing options like A-frame and butterfly designs can maximize space utilization while ensuring proper drainage and ventilation for their container projects.

About Shipping Container Roof Basics

Standard shipping container roofs require significant modifications before becoming suitable for residential or commercial use. Understanding these fundamental requirements helps create safe and durable shipping container roof ideas that stand the test of time.

Why standard container roofs need modification

The original design of shipping container roofs focuses primarily on cargo protection rather than structural support. Standard container roofs can withstand only 330 pounds per square foot according to ISO requirements. Notably, this capacity decreases substantially once modifications begin, particularly during side panel removal.

Furthermore, water pooling presents a significant challenge with standard container roofs. Despite their convex design, these roofs don’t shed water as effectively as traditional sloped structures. Consequently, standing water can lead to several issues:

- Rust development

- Metal thinning

- Moisture intrusion

- Potential mold growth

Key structural considerations

The structural integrity of shipping container roof ideas depends primarily on the corner castings rather than the roof itself. Specifically, the load-bearing capacity varies based on three distinct categories:

- Dead loads: Combined weight of walls, equipment, and furniture

- Live loads: Weight of people walking or working on the roof

- Transient loads: Natural stresses from rain, wind, and snow

Moreover, any modifications must account for the container’s monocoque structural design. The roof panel works in conjunction with side walls to maintain overall stability. Particularly, removing side corrugated paneling requires additional steel reinforcement above the openings.

The permissible loading capacity follows strict guidelines, with the Container Safety Convention (CSC) stipulating that roofs must withstand 200 kg loads over an area of 600 x 300 mm. For areas experiencing severe winter conditions, shipping container roof ideas must account for a 25 psf dead load plus 40 psf snow load.

Additionally, structural engineers recommend treating modified containers as relatively weak structures, therefore necessitating support beams spanning between corner posts. This approach ensures roof stability without relying solely on the container’s original integrity.

Popular Shipping Container Roof Designs

Modern shipping container roof ideas have evolved beyond basic coverage to offer both functionality and style. Each design serves specific purposes, from simple weather protection to creating additional living space.

Flat roof modifications

Flat shipping container roof ideas remain the most straightforward option for many projects. These roofs feature a slight pitch, typically 1-2 degrees, to facilitate water drainage. For enhanced protection, builders often apply:

- Galvanized metal sheets

- Coated steel panels

- Asphalt rolls with tarpaulin underlayment

- Industrial-strength 22-gage steel panels

Sloped roof options

Sloped shipping container roof designs primarily focus on efficient water management and enhanced insulation. The shed-style roof, essentially a single-slope structure, offers excellent drainage capabilities. Subsequently, these roofs provide ideal surfaces for solar panel installation, making them perfect for sustainable container homes.

Gable roof structures

Gable shipping container roof ideas create the classic A-frame appearance, undoubtedly the most traditional-looking option. This design requires installing rectangular steel plates across the container’s perimeter. The installation process involves:

- Welding right-angled steel plates along the container length

- Attaching wooden beams to steel plates

- Securing trusses to wooden beams

- Installing purlins for structural support

The gable design excels in areas with heavy rainfall or snow, since its 40-degree angle allows for optimal drainage. Alternatively, builders can choose between shingles or coated steel sheets for the final covering. Moreover, for proper ventilation, trusses should extend beyond the container edges, incorporating mesh-covered air gaps.

Inside mount installations offer cost savings due to narrower roof spans. Outside mounts, alternatively, provide additional coverage and storage possibilities above containers. Western Shelter Systems offers standardized options ranging from 20’x20′ to 40’x40′ usable areas, whereas Curvco Steel Structure provides American-made roofing kits spanning 20′ to 80′ in width.

Step-by-Step Roof Installation Guide

Proper installation of shipping container roof ideas requires careful planning and precise execution. Initially, understanding the complete process helps ensure successful implementation while maintaining safety standards.

Required tools and materials

Installing shipping container roof ideas demands specific equipment and materials. A basic toolkit should include:

- Essential Equipment:

- Measuring tape and string for alignment

- Step ladder for access

- Welder for structural connections

- Sledgehammer for adjustments

- Wrenches for securing bolts

- Scissors for material cutting

Alternatively, advanced projects might require specialized equipment. Generally, a small team of 3-5 people can complete a 30×40 container roof installation within a few days. Although scissor lifts offer convenience, ordinarily basic tools suffice for most installations.

Safety precautions

First thing to remember, falls account for three-fourths of all fatalities in the roofing industry. In order to ensure worker safety, OSHA mandates specific requirements for shipping container roof projects. Critical safety measures include:

- Mandatory fall protection for heights above 6 feet

- Personal Fall Arrest (PFA) systems including body harnesses

- Proper ladder positioning extending 3 feet beyond roof edge

- Regular inspection of all equipment by qualified personnel

A competent person must train workers to recognize potential hazards. This individual should possess the authority to implement immediate corrective measures when identifying unsafe conditions.

The installation process primarily focuses on structural integrity. Load-bearing calculations must account for:

- Dead loads from construction materials

- Live loads from workers and equipment

- Environmental stresses like wind and rain

For proper ventilation, shipping container roof ideas should incorporate an inch-wide air gap in soffit boards, protected by wire mesh. This design feature prevents condensation and rust formation while ensuring adequate airflow throughout the structure.

Professional structural engineers play a vital role in determining specific load-bearing requirements. Their expertise ensures compliance with local building codes and accounts for regional weather conditions that might affect the roof’s stability.

Material Selection for Container Roofs

Selecting appropriate materials stands as the cornerstone of successful shipping container roof ideas. The right combination of materials ensures longevity, weather resistance, and optimal performance across varying climate conditions.

Metal roofing options

Shipping container roof ideas primarily rely on industrial-strength steel panels for superior durability. In particular, COR-TEN steel, a self-healing metal variant, offers exceptional rust resistance and tensile strength. Furthermore, the standard thickness ranges from 1.6mm for roofs to 2mm for walls, providing robust protection against environmental stresses.

American-made steel roofing kits, manufactured by companies like Shield Roof Solutions, come with impressive 20-year guarantees. These 22-gage industrial-strength panels simultaneously deliver durability and minimal maintenance requirements. Evidently, metal roofing reflects solar radiation, reducing cooling costs by up to 40%.

Insulation materials

Presently, shipping container roof ideas incorporate comprehensive insulation systems to regulate internal temperatures effectively. The selection process focuses on:

- Closed-cell high-pressure fused EPS Insulation

- Continuous insulation panels

- Ceiling inserts for corrugated spaces

Container insulation requires careful consideration of surface temperatures, with optimal bonding occurring above 40°F (4°C) and below 90°F (32°C). Forthwith, proper R-value calculations determine the insulation thickness needed for specific climate conditions.

Waterproofing solutions

Polyurea emerges as a highly effective waterproofing solution for shipping container roof ideas. This coating provides several advantages:

- Maintains flexibility in temperatures below zero

- Resists cracking and peeling

- Offers superior insulation properties

- Enables rapid application of up to 1000m2 daily

High-quality sealants, specifically designed for metal structures, accommodate metal expansion and contraction while maintaining tight seals. Alternatively, industrial-grade weatherproof barriers and membranes add extra protection against moisture penetration.

Regular maintenance plays a vital role in preserving waterproofing integrity. Periodic inspections of roofs and seams, combined with timely reapplication of sealants and coatings, prevent potential water-related issues. The combination of proper materials and maintenance procedures ensures shipping container roof structures remain watertight and durable throughout their service life.

Cost Breakdown and Budgeting

Building a budget for shipping container roof ideas requires careful consideration of both material and labor costs. The financial investment varies significantly based on design complexity, material selection, and geographical location.

Material costs

The foundation of shipping container roof ideas starts with the basic structure. A standard shipping container roof kit ranges from USD 5,500 to USD 13,000, primarily depending on strength requirements and utility features. For those seeking premium options, specialized designs like the Gable 20 cost USD 16,571, extending to USD 29,533 with additional features.

The cost per square foot for shipping container roof materials fluctuates between USD 8.00 to USD 18.00, certainly influenced by:

- Model specifications

- Size requirements

- Local building codes

- Snow and wind load requirements

Metal roofing materials, straightaway becoming the most popular choice, typically cost between USD 5.00 to USD 10.00 per square foot. Alternatively, wood or composite siding ranges from USD 8.00 to USD 20.00 per square foot.

Labor estimates

Labor costs for shipping container roof ideas vary significantly across regions. Professional installation teams typically charge between USD 225.00 to USD 280.00 per square for basic field panel installation. Nonetheless, union shops might quote USD 800.00 per day per roofer.

Installation efficiency plays a crucial role in labor costs. A skilled team can complete:

- Basic field panels in approximately 3 man-hours per square

- Simple ranch-style installations in 3 to 3.5 hours

- Complex projects with valleys and hips requiring additional time

Regional variations significantly impact total costs. For instance:

- Central Minnesota reports rates of USD 600.00-700.00 per square

- South Florida averages USD 600.00-700.00 per square

- Denver maintains rates around USD 500.00-550.00 per square

The installation timeline primarily depends on project complexity. Soon after preparation, a small crew can typically complete a standard roof installation within a weekend. Hence, labor costs remain manageable with proper planning and efficient crew coordination.

Structural considerations often necessitate additional expertise. Professional engineering consultations range from USD 1,500.00 to USD 3,000.00, therefore ensuring proper load calculations and design specifications. For comprehensive projects, site preparation and foundation work might add USD 1,000.00 to USD 3,000.00 to the total budget.

Opening modifications, comparatively smaller yet essential components, typically cost USD 100.00 to USD 500.00 per cut. These modifications must accommodate proper ventilation and structural integrity while maintaining budget constraints.

Shipping Container Roof Ideas Frequently Asked Questions

What is the average cost of installing a roof on a shipping container?

The cost of installing a roof on a shipping container typically ranges from $8 to $18 per square foot. Factors affecting the price include the size of the container, model specifications, and local building requirements for snow and wind loads.

How much weight can a 20-foot shipping container roof support?

Standard shipping container roofs are designed to withstand approximately 330 pounds per square foot. However, this capacity can decrease significantly once modifications begin, especially if side panels are removed.

What are the main challenges of using shipping containers for housing?

Some challenges of using shipping containers for housing include difficulty fitting standard appliances, obtaining building permits, finding experienced contractors, addressing insulation issues, and adapting to climate conditions. Additionally, there may be safety concerns with used containers and limitations in shape and size.

What are the best insulation options for a shipping container roof?

Popular insulation options for shipping container roofs include closed-cell high-pressure fused EPS insulation, continuous insulation panels, and ceiling inserts for corrugated spaces. The choice depends on climate conditions and desired R-value.

What are some popular roof designs for shipping container homes?

Popular roof designs for shipping container homes include flat roof modifications with a slight pitch for drainage, sloped shed-style roofs ideal for solar panel installation, and gable roof structures that create a classic A-frame appearance. Each design offers unique benefits in terms of water management, insulation, and space utilization.